Use Cases

Predictive Asset Performance Management for Oil and Gas

The harvesting and processing of energy resources requires efficient management and optimization of machine and device assets. Whether it be oil or natural gas, those assets perform critical functions within every phase of the energy harvesting, refinement, storage, and delivery ecosystem.

Historically, the oil and gas industry has relied on manual, static, human-managed, methodologies and processes to keep production assets performing safely and reliably. To reach higher levels of Overall Equipment Effectiveness (OEE), improved cost control, and enhanced safety, new technology-enabled solutions are required.

IIoT (Industrial Internet of Things), combined with generative AI, and predictive analytics drive improvements in asset productivity, reduce downtimes, and minimize operational risks.

Current Challenge

Common Problems Faced by Enterprises

The transition from reactive to preventive asset management back in the late 1990’s provided the oil and gas industry with much-needed improvement in the management of mission-critical assets. However, technology is never static and what was considered cutting-edge then is considered outmoded today. As the competitive and regulative landscapes have changed, the shortcomings of legacy preventive management solutions have become increasingly apparent. Shortcomings that include:

01

Lack of actionable, real-time, asset data

Legacy asset management protocols are based entirely on historical data. History is not always an accurate predictor of current and future conditions. This often creates a wide intelligence gap.

02

Manual processes

Manual processes, siloed systems, and disconnected assets create service inefficiencies, asset degradation, and negative bottom-line impact.

03

Inability to predict failure

No ability to predict the potential for catastrophic failure due to lack of AI-enabled, asset-specific, predictive analytics. This creates increased potential for an emergency at the asset and/or operational level.

04

Static preventive maintenance routines

The reliance on manual maintenance processes that consume human resources and that are prone to error. Preventive routines that often create unnecessary downtimes and production loss.

The Solution

AI Enabled Predictive Asset Performance Management

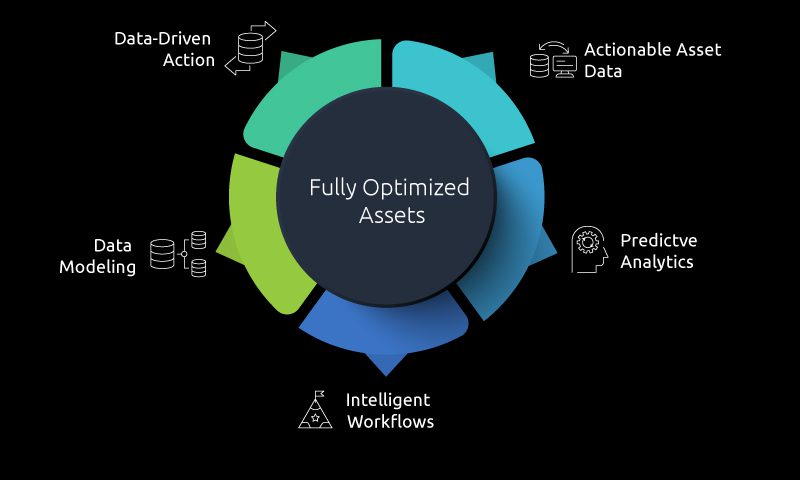

The Predictive Asset Performance Management Ecosystem

The Impact

The Operational Impact

- Optimized utilization of data generated by machine assets regardless of geographical location

- Reduction in waste resulting from sub-optimized asset performance

- Closed-loop elimination of repetitive issues

- Extended lifespans of capital-intensive assets

- Enhanced visibility into compliance-critical processes

- Reduced operational cost via deeper visibility, more predictability, and increased reliability